07/06/15

"How I Do It"

Engine Removal

|

The "normal" method of engine removal is to take off the hood, attach the hoist and

raise the engine. In order to clear the radiator support, the engine has to be raised fairly high

into the air. Yes, it is done every day, and I've done it quite a few times myself, but still,

that is one whole lot of weight to be swinging around so high in the air.

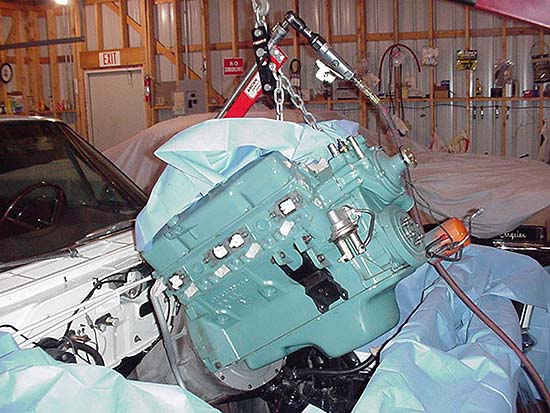

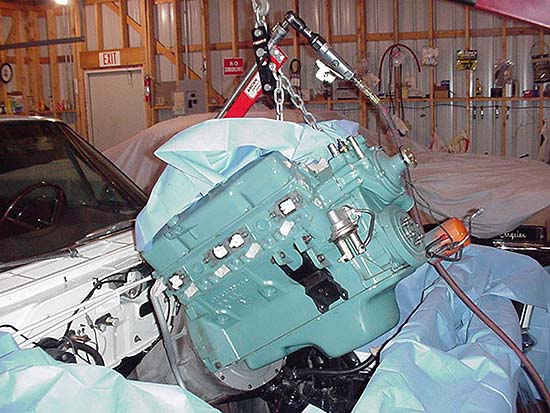

In this picture I am installing a new engine into a newly painted 66 Chrysler.

I did it without a scratch in any of the new paint, a situation

unlikely to be reliably repeated in future projects.

Removal or installation of the engine, no matter. It is still a lot of weight high in the air.

|

|

|

Here we are working on a 300J. The engine and transmission

had to come out for rebuild. Unlike the other garage, this

garage does not have a solid level concrete floor. The floor

is old, pitted, rough, and slopes slightly to an old drain.

The engine hoist does not like to move over the rough floor

and once it gets moving, the hoist is hard to control as it wants to follow the

slope of the floor.

I got to thinking that for this situation, I'd rather not have the engine

so high during removal and a plan was hatched.

If I removed the grille, the radiator support, and the sheet metal

around the grille, I wouldn't have anywhere near the "lift-over" height.

Fortunately, this car was

rust-free so those little fasteners came off without

complaint or fracture and in short order I had those pieces off.

|

|

|

The engine does not have to be lifted very far to clear the frame. You can even leave

the hood installed since the hoist arm does not elevate very much.

|

|

|

Without much effort, the engine and transmission are safely out.

|

|

|

The pictures on this page show the engines hoisted with

a leveling device.

These are essential to provide the tilt needed to allow things to clear

frame rails and floors.

In most cases the engine needs to

tilt quite a bit.

|

|

Over the years I've collected three level devices.

Not all are built well.

The level pictured to the right is one of my favorites.

It is rugged and reliable.

|

|

|

This level device has also worked

well and comes in as a second favorite.

If it was more rugged in construction,

especially in the lifting hook, I would like it better.

|

|

|

This level device I would not

recommend.

You see the top side is open.

Under load, the gap on top spreads.

Although I have never had the

inside rollers pop out, it is not

a comfortable site to see

the device spreading under load.

|

|

|

If you work with a leveler that has the

chains going through eyes as this one does.

it makes a difference how you route the chains

through the leveler.

With the chains routed as in this picture, the

engine wants to rotate when lifted.

If I routed the front chain and rear chain

through the eyes in opposite directions,

the engine would not be trying to rotate.

|

|

|

One last tip:

Apply light lubricant to the sliding surfaces

of the level device and things

will work much easier.

|

Back

|