|

F, G Heat Riser

March 5, 2022

One cold winter's day we got looking at F and G exhaust manifolds and the heat risers.

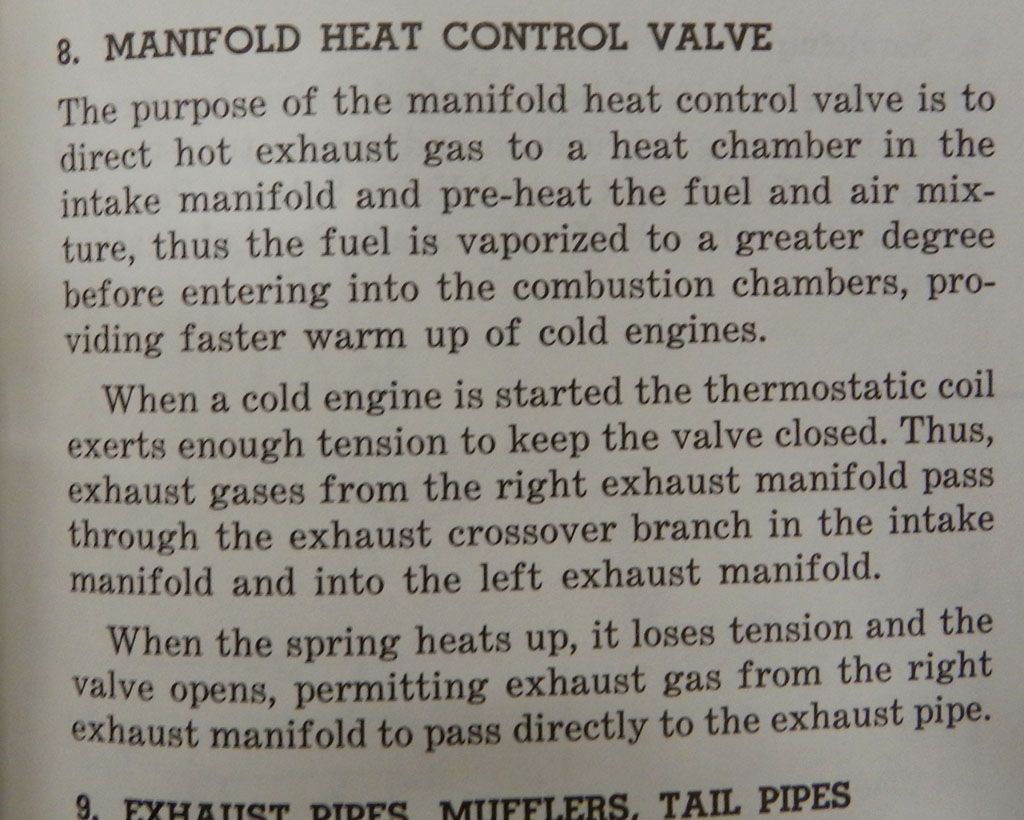

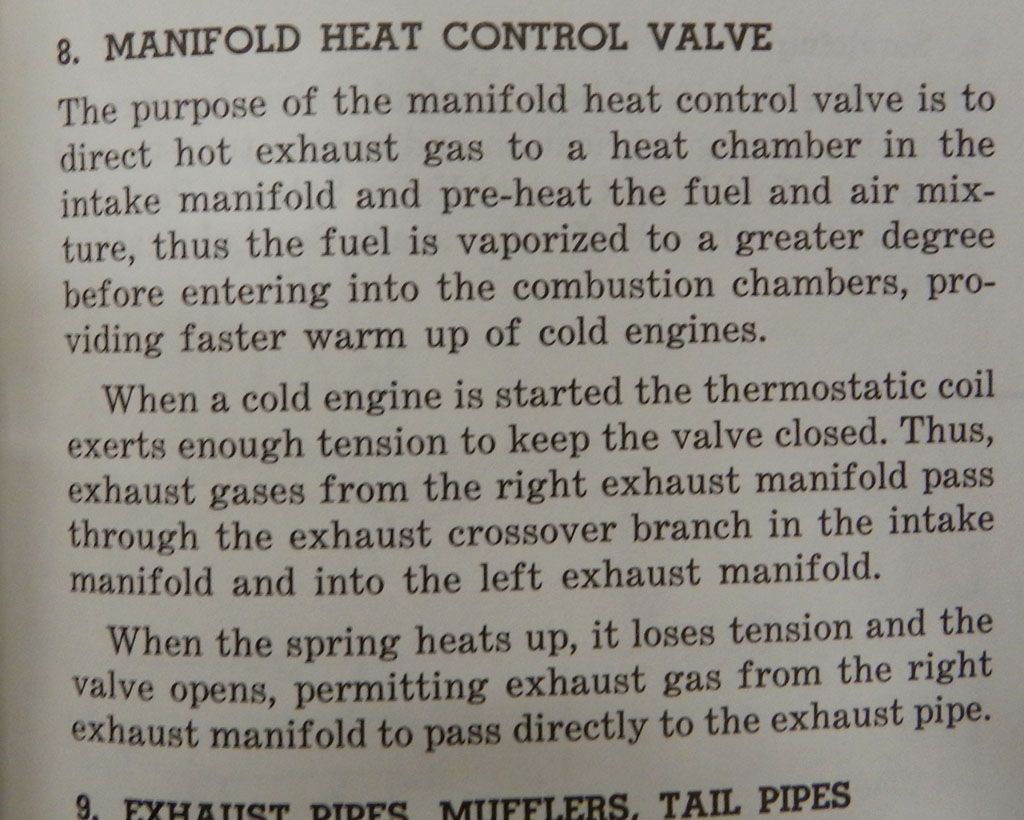

The service book calls them "exhaust manifold heat control valves" but

heat risers is easier to type.

If you wonder what they do, read the picture to the right.

Leaving out the J and ram K, all of our Letter Cars

have a heat riser except for the F and G -- they have two heat risers.

They need two because of the location of the carburetors; way outboard

at the end of the rams, and both carbs need heat. For the passenger side

carb, heat from the passenger side exhaust is easy and the

heat riser resembles the one found on many RB engines.

The fun starts on the driver side exhaust manifold. Here another

heat riser is needed but it is a mirror image of the passenger side.

Heat riser parts for the driver's side are unique to the F & G and near impossible to find.

Let's get into the heat riser springs.

We dug up two G passenger side manifolds complete with the heat risers.

We found that both have a 6 coil spring and the spring is .250" wide.

We also dug up two driver side G manifolds. Each of them has a heat riser spring of

4 coils at .250" wide.

We also dug up two driver side G manifolds. Each of them has a heat riser spring of

4 coils at .250" wide.

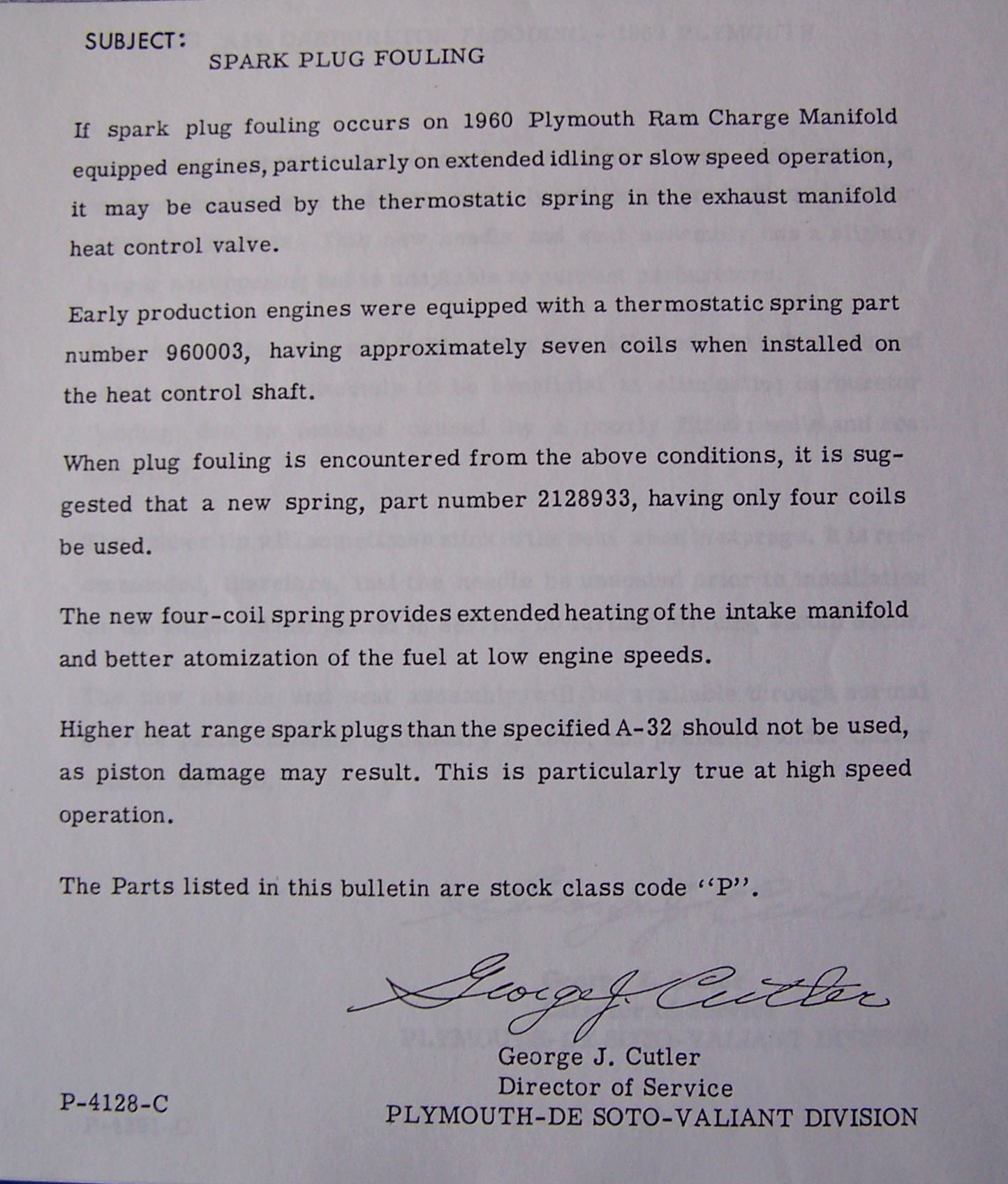

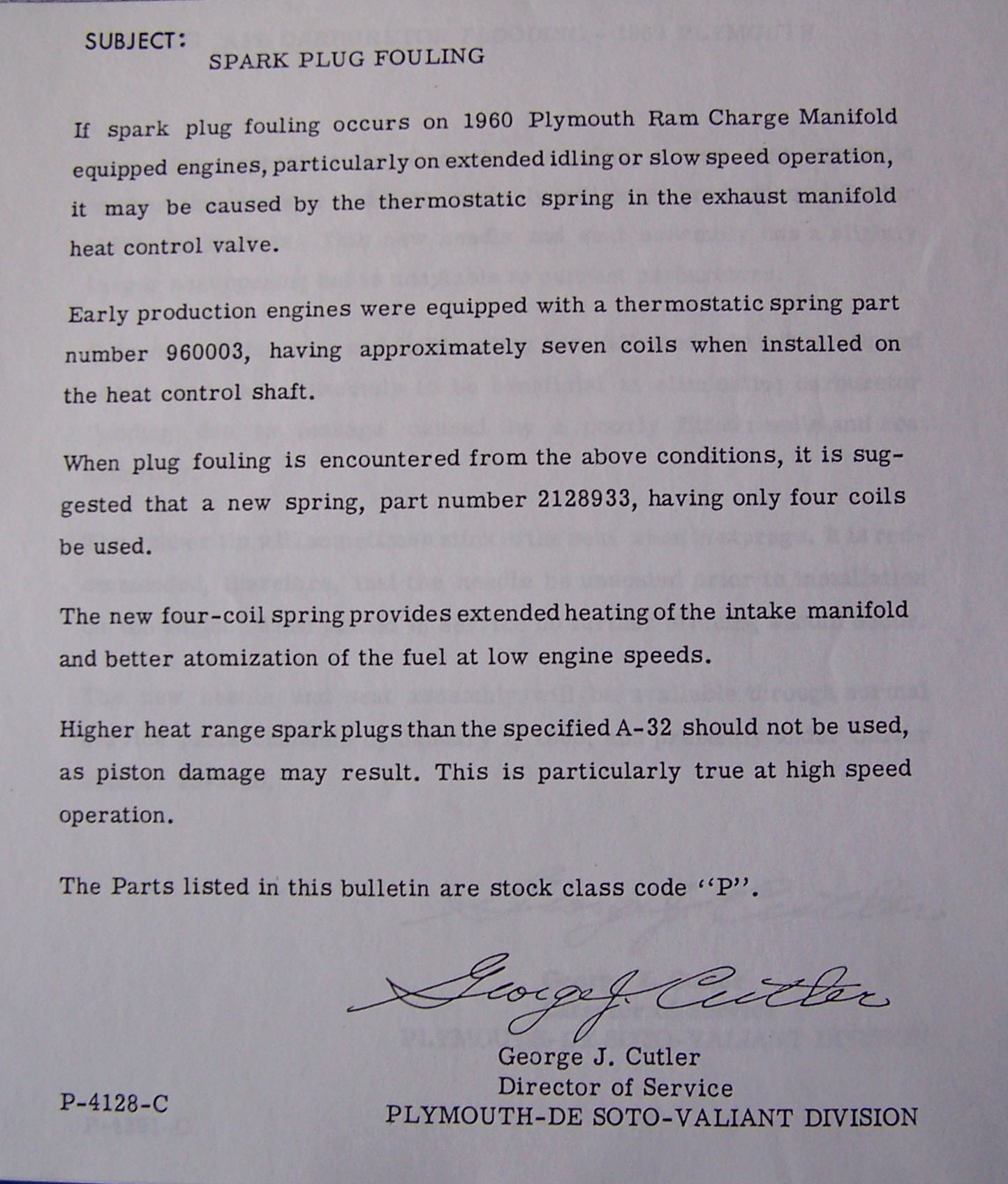

There is a Plymouth service bulletin that says the spring should have 4 coils.

I have that pictured to the right.

Actually, there are two Plymouth service bulletins, one from November of 1959

says 4 coils and one from August of 1960 says 5.

Then there is this service bulletin #60-49 from May 1960 for the 300F which says 5.

But neither bulletin says which side or if both sides get the 4 - 5 coil springs

so we took our question to the web.

Don Verity wrote;

Don Verity wrote;

The enclosed picture (left) shows 2 original springs on the bottom and 2 NOS ones on top.

The passenger riser and the driver riser use the same 4 coil spring.

My thoughts on these heat risers. Yes, they are necessary. They help in cold warm up, and are needed for the automatic chokes to open in a short amount of time. If both chokes open fully when warmed up, I don't think it makes any difference if one opens slightly faster than the other. A higher idle on one carb is going to make the other carb stay open the same amount because of the connector linkage. It will not make a difference unless one choke is grossly tighter than the other. I plan to adjust mine so they open as close to each other as possible. Yes, it's an imperfect system, but it works well for the period it was designed.

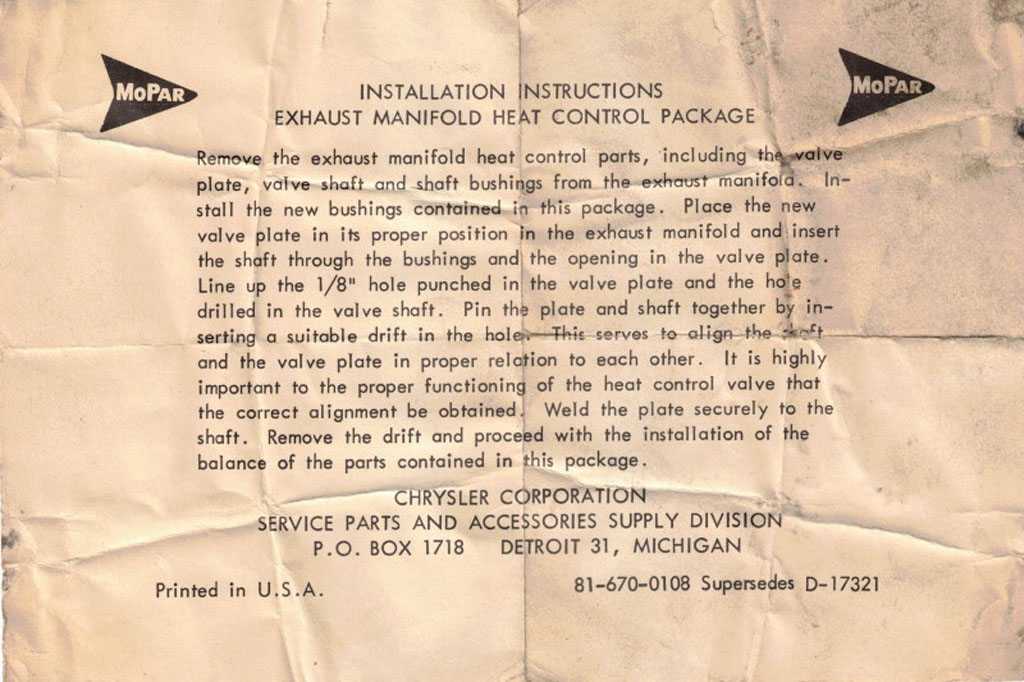

The later units on some vehicles that used timed vacuum, seem to be more reliable and less prone to getting stuck. If you put new bushings in the old manifolds, they will also need to be reamed out or they will be too tight. The later units on some vehicles that used timed vacuum, seem to be more reliable and less prone to getting stuck. If you put new bushings in the old manifolds, they will also need to be reamed out or they will be too tight.

Jim Mikolajczak writes:

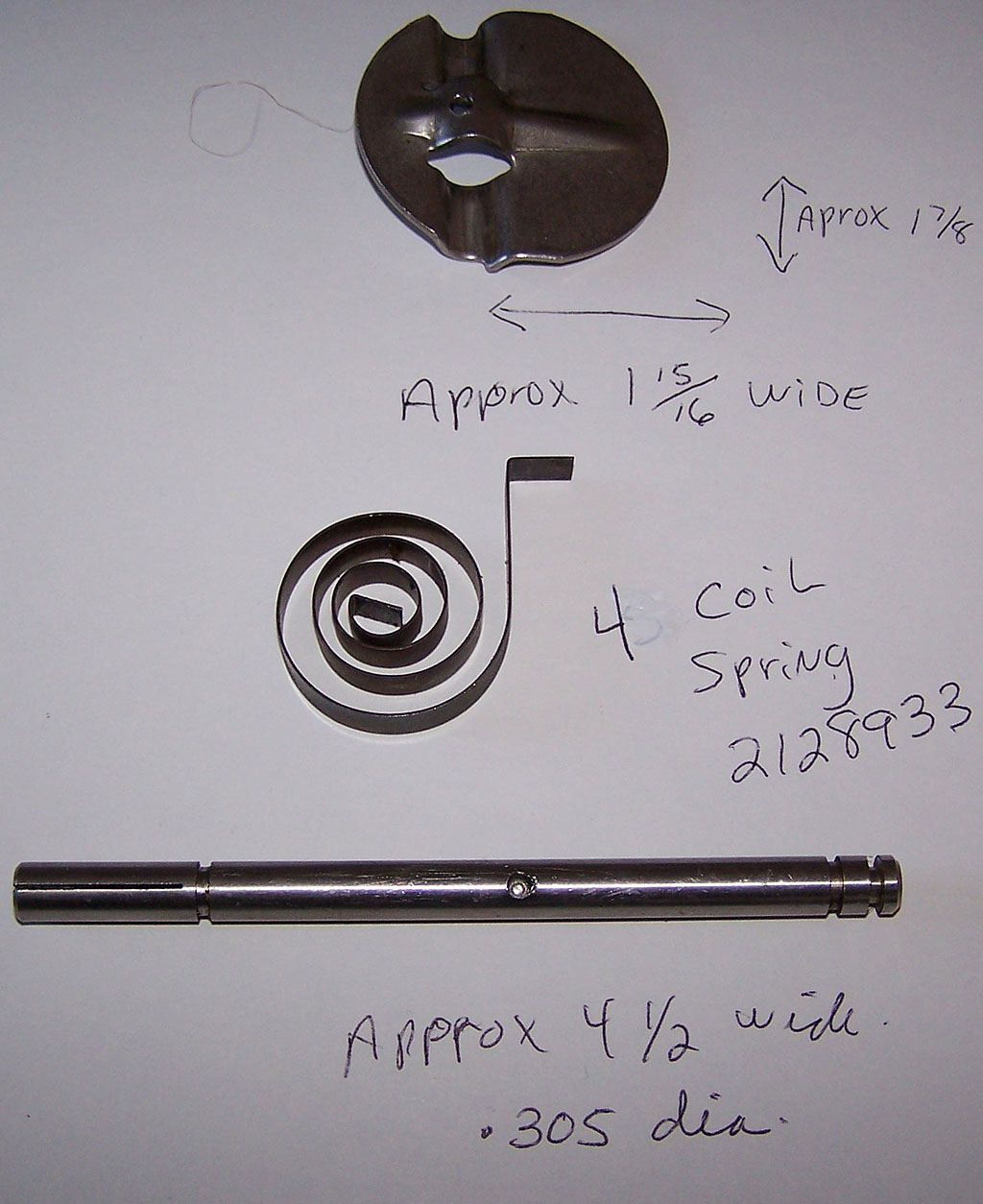

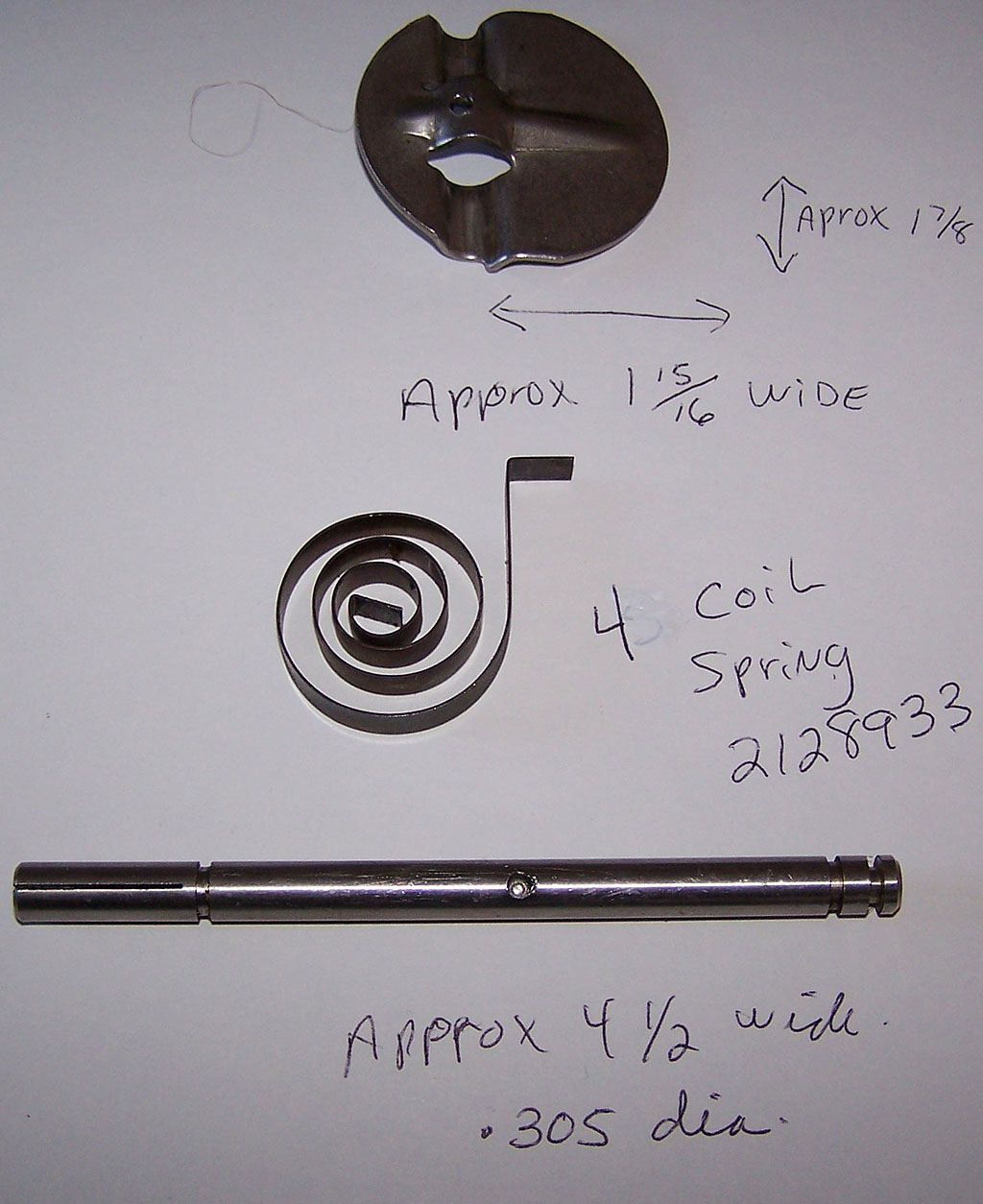

I've done quite a few of these. I found reaming the bushings after installation to .3110 works well. The shaft will bind when it heats up if there is insufficient clearance. A nos shaft is about .305. Totally agree with Don. They are necessary to open the chokes quickly to avoid oil dilution and potential spark plug fouling.

Nick Taylor writes:

I was looking in the revised 1960 parts book last night and they show the same thermostatic spring for both sides and the part number is the one from the bulletin (2128933).

Good Stuff! Now we know what coil sping we need, but then the question

is where to get it.

Marshall Larson writes:

Marshall Larson writes:

This is the spring that I have used on both sides. They fit with no modification of any kind.

It is from Chevs of the 40s, their part number 838573.

I have noticed over the years at shows and meets most people need to restart their cars multiple times before they will stay running and they are able to drive away. Mine stay running and I can drive away immediately. That requires working chokes and heat risers. I don't believe the rate at which the risers open is as important as that they close for cold start. I suspect that no one uses their cars in really cold temperatures.

Andy Mikonis writes:

I researched this a while back and I have one apart. See photo.

Jean-Yves writes:

Here'a a picture of John's driver side heat riser, just taken off a Nevada 300F.

It is complete...it still has the often missing stopper, although this stopper is missing its heat resistant material that is usually wrapped around it. This one looks to have 3.5 coil wrap count.

We released the round butterfly flap from the shaft in order to remove the thing off the manifold by grinding the welds carefully with a small pointed carbide tip on an air tool.

Nick Taylor found a left side heat riser kit on Ebay and sends these pictures:

Where do we go from here?

We are making good progress on having ram heat riser pieces fabricated

and we have springs coming in for evaluation.

I will update this page

with our progress.

We have a video of our adventures.

Back

|