|

AstraDome

Amp Gauge Problem and Repair

By

Dave Mason

Symptoms:

Smoke

from somewhere around instrument cluster.

Gauges

reading all the way high.

Troubleshooting:

Because

the gauges were reading all the way high, I was prompted to inspect

the grounding. The original ground wire looked burnt. I checked

continuity of Astradome gauge housings to ground and found they were

not grounded. I disconnected the battery, made a new ground wire,

installed it, checked continuity of housings to ground, and

reconnected the battery. More smoke. I disconnected the battery

again, inspected the new ground wire and found it to be burnt.

Because the heavy gauge wire feed to the amp gauge is always hot, I

suspected a problem here, and checked continuity of amp gauge voltage

feed posts to ground and found continuity. This meant that the hot

feed to the amp gauge was being grounded out which made sense to

explain the burnt ground wires.

Repair:

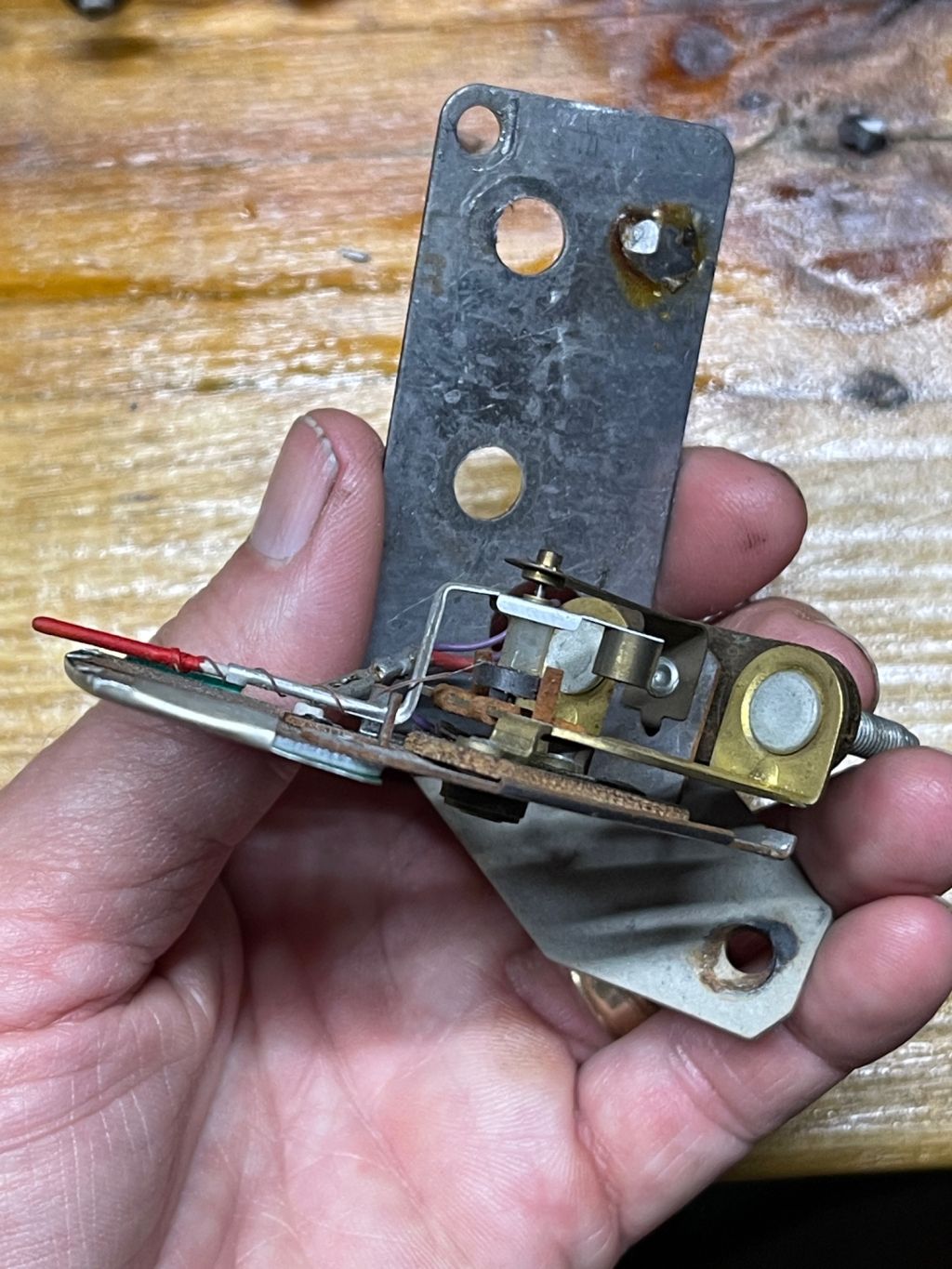

Upon

removing the amp gauge and inspecting it more closely I looked for

any place that carries voltage that should be insulated from the

housing.

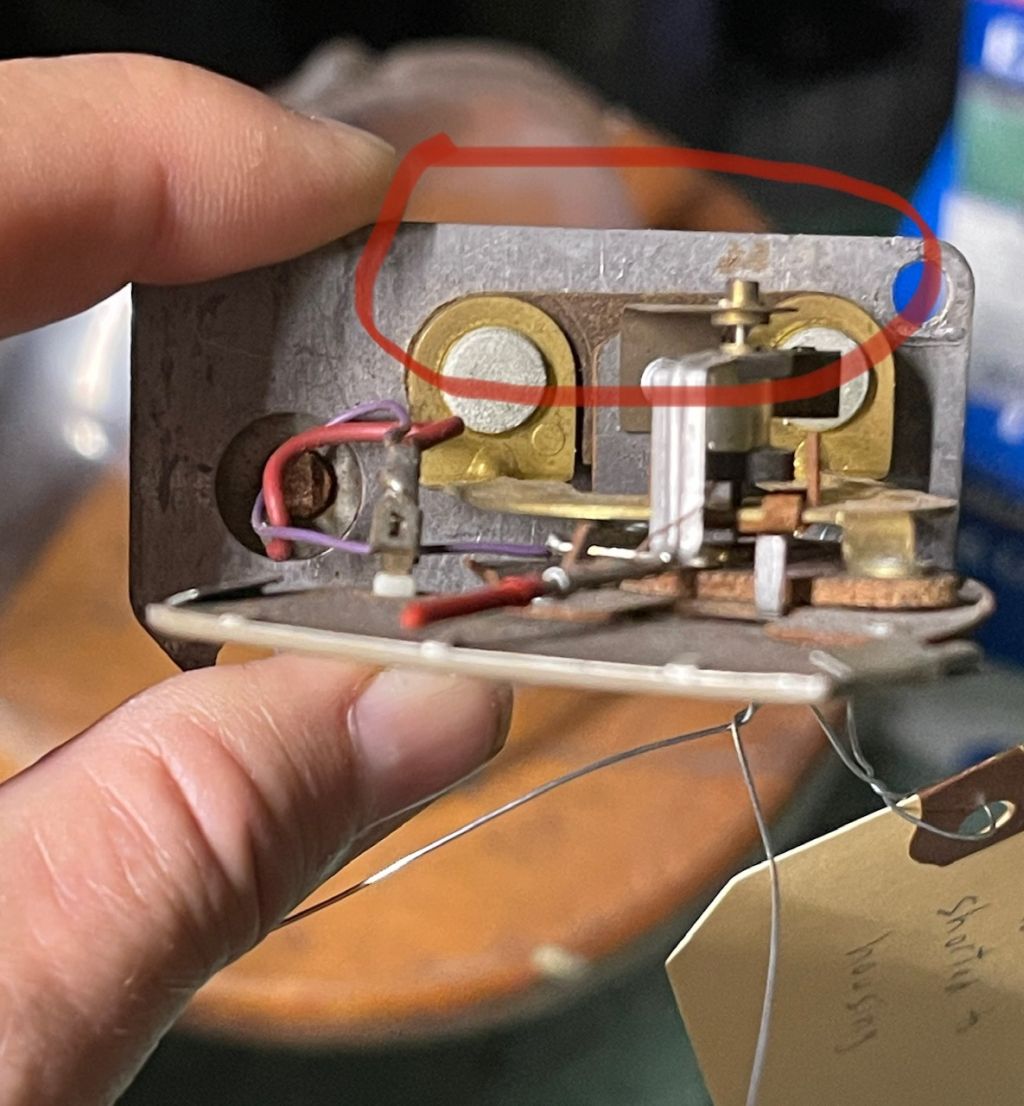

The

threaded posts are essentially a pass-through of current flow (in one

and out the other), and the gauge indicates direction of current and

relative amount. Therefore the gauge housing (designed to be the

ground) must be insulated from any part of the gauge which touches

the hot voltage. Here are the points which need to be insulated:

There

was no visible problem to be seen here except

I

therefore needed to get a better look into this area. So

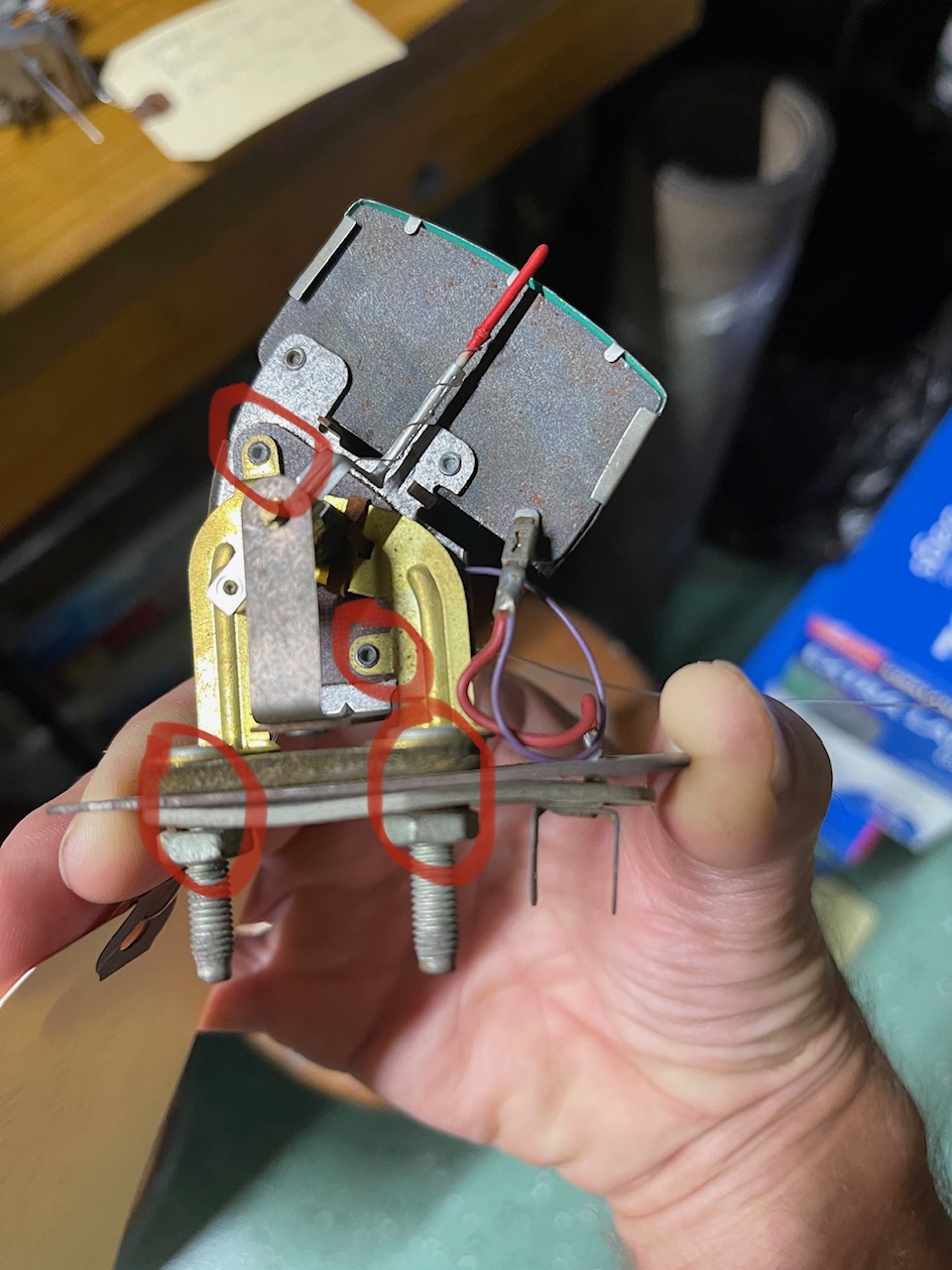

this post needed to be pushed away from the housing. After

straightening the posts and looking closely, although they were now

pretty well Note:

I did not need to unsolder the After

enlarging the post holes a little I reassembled and resoldered the

joint. Because

there are metal split ring washers pressing directly on fiberboard, I

added some flat stainless washers to prevent a metal split ring edge

from digging into the insulating fiberboard:

Snugged

up the nuts carefully and re-checked continuity between the

|