by Carl Bilter

September 22, 2011

Replacing the oil pump on the 413 engine is a fairly easy "do it yourself" project (with a couple caveats listed later). The first issue is determining when the oil pump needs replacing and what type of pump should be used for the replacement pump.

The factory provided us with an extremely stout, long-lived oil pump. It is not unusual for the 413s to have their original oil pumps, even on relatively high mileage engines. Therefore, short of the pump actually being able to pump oil up through the engine, the most likely reason to replace the pump is due to a leak. The pump can actually be rebuilt, but as new replacement pumps are readily available at your local auto parts store at relatively low cost, buying a new pump might be easier and ensures all the parts are new. The oil pump body is comprised of two pieces which are bolted together and contain an internal seal or gasket. This seal is the likely source of leaks after 50 odd years of service, and oil will drip from the lowest mounting bolt when the engine in running.

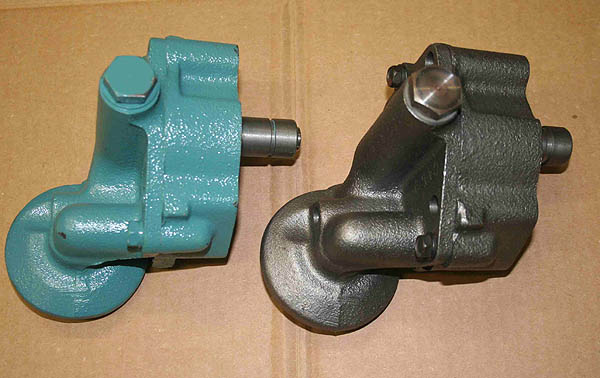

Several types of replacement pumps are available. The factory used a standard volume, standard pressure oil pump. This type of pump is fully adequate for use in the letter cars. A high volume pump is also available. The high volume pump has a similar physical configuration to the standard volume pump but has a larger (deeper) body (see picture).

Mopar Performance offers this high volume pump as part #P4286590. A high volume pump moves more oil by volume than a standard pump, but not necessarily at a higher pressure. The high volume pump is designed primarily for racing applications. When cruising, the high volume pump may simply cause more oil to dump back directly to the oil pan or pump inlet, as pressure is controlled by the relief spring in the pump.

It is also possible to purchase a high pressure oil pump. The difference between the high pressure and standard pressure pump is in the relief spring. The factory used a 55PSI spring in the standard pump. A general rule of thumb is that 10PSI per 1000 rpm is usable for most engines; so a standard pressure pump should be fine. The pump will move a set amount of oil per revolution of the pump. The clearances between the shafts and bearings in the engine, along with the viscosity of the oil determine the final oil pressure. The 413 doesn't require a lot of oil pressure actually, but rather a good supply of oil. A high pressure oil pump can actually damage the bearings.

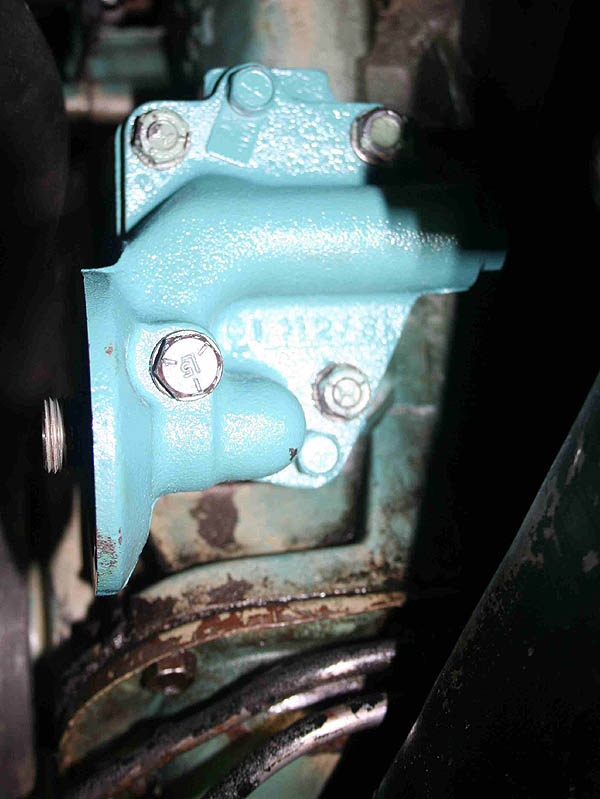

Replacing the pump is relatively easy, unless you have sagging or broken motor mounts or some other frame obstruction that prohibits easy removal of the pump. The factory was kind enough to provide us with an external oil pump located at the bottom and front of the engine on the driver's side. On the 300J, no frame obstructions are present that interfere with removing the pump from under the vehicle. If you have a sagging or broken motor mount on the driver's side, it may be necessary to jack up the engine slightly to allow the pump to clear the sway bar, but probably not likely. The lower radiator hose does not need to be removed as it does not interfere with the pump. The oil filter should be removed first before unbolting the pump. Have a drain pan under the car to catch the oil from the filter and the pump, but it won't be too messy as most of the engine oil is down in the oil pan.

This picture shows the original oil pump taken from the 300J along with the new pump, which is a Perfect Circle part # 601-1067 that I bought and painted back in 1990, but was never installed. It was painted in Mopar Performance turquoise engine enamel, which incidentally does not match the original teal green paint on the factory oil pump particularly well. This oil pump used to be carried by NAPA and numerous other stores but may no longer be available. NAPA currently has an oil pump made by Sealed Power, part # 2244174, for about $56 (Fall 2011) and other stores have a Melling pump, part #M63, for about the same price that will fit.

When installing the new pump, fill the pump cavity with as much oil as possible to help with the initial prime, and also fill the oil filter. Use the new gasket and O-ring supplied with the new oil pump. Install the pump on the engine first, and then install the oil filter on the pump. Torque the oil pump mounting bolts to the factory specified setting of 35 ft-lbs. (see picture of new pump installed on the engine).

As the filter sits horizontally, it is not practical to get too much oil in the filter as it will spill out during installation. The idea is to keep as much oil in the filter as feasible to aid in initial priming of the oil pump. Add enough oil back in the engine to compensate for what was lost during the pump removal process, and you are ready to go. Assuming you do not have a freshly rebuilt engine, the new oil pump has tight clearances and will prime when you start the vehicle. Technically, this has to do with the type of pump (positive displacement pump) and the difference in height between the pump rotor and the fluid sump. Suffice it to say that the oil pump in our vehicles is designed to establish prime very quickly. Avoid fast idle until oil pressure is adequate (or, in the case of the 300J, the oil pressure light goes off). Note: a freshly rebuilt engine requires a more complicated procedure for initial start-up that is beyond the scope of this article